New Shengli suspension furnace F-300

Classification:

-

Subject: Suspension furnace, rice husk hot air furnace

Usage: Can supply materials to multiple dryers, suitable for burning rice husk

Material: Stainless steel

Highlights: Suitable for rice mills, rice husk can be used directly as fuel, saving fuel costs

Rice husk hot air furnace design features

1. The furnace (combustion chamber) is made of high-quality carbon steel, making the rice husk hot air furnace more sturdy and durable.

2. The furnace is equipped with refractory materials, and the exterior is sprayed with black baking paint, which is resistant to high temperatures and has a long service life.

3. Heat exchanger: Made of 60*6000mm steel pipes arranged vertically, the inner wall of the pipe does not accumulate ash (smoke dust), reducing thermal resistance, and the middle layer is insulated with rock wool, improving the thermal efficiency of the rice husk hot air furnace.

4. The operation panel buttons are simple and clear, the functions are clear, the operation is simple, and the degree of automation is high.

5. Using rice husk as fuel, the combustion cost is extremely low.

6. Converting the organic waste rice husk into usable resources, the ash from combustion can be used as industrial insulation materials, organic fertilizers, or agricultural media, etc., recycling renewable energy and achieving environmental protection effects.

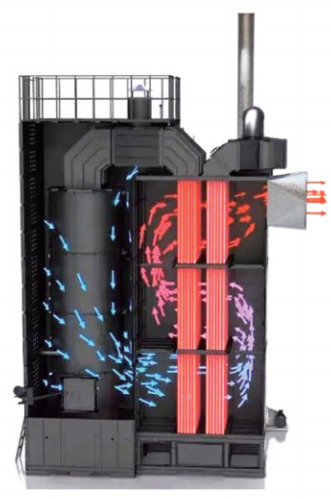

Rice husk hot air furnace component names

① Feeding system ② Exhaust system ③ Hot air outlet ④ Heat exchange system ⑤ Guardrail, ladder ⑥ Furnace body ⑦ Electrical control box ⑧ Exhaust fan ⑨ Oxygen supply system ⑩ Automatic ash removal system ⑪ Ash storage bin ⑫ Rice husk bin

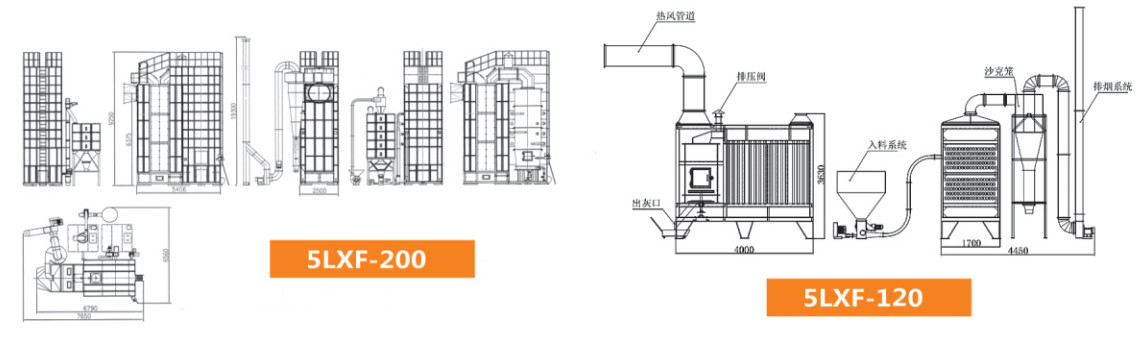

Structural diagram

Rice husk hot air furnace working principle diagram

Technical parameters

Key words:

New Shengli suspension furnace F-300